Our History:

Claasens Designs CC is a proudly South African family business that manufactures and provides the best biltong slicing equipment in the market. The CLAASENS rotating biltong slicer was developed and commercialized in 1955. We are enthusiastic about producing high-quality products designed to be efficient and durable. Our biltong slicers are well known for its uniqueness based on the original patent.

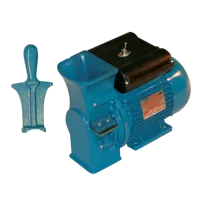

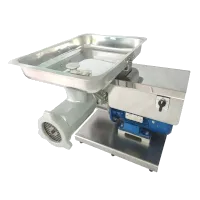

The very first rotating biltong slicer was made of wood and pieces of scrap steel. Four blades were radially staggered to cut continuously, from which the spiral blade design was derived. Development of the prototype electric biltong slicer followed the manual slicer, also with a humble constitution of materials! Quite a design progress was made over the years. See photos of the original hand and electric biltong slicers, and those of today.

Original Design

First Hand Slicer Prototype

First Electric Slicer Prototype

New Design

Todays Hand Biltong Slicer

Todays Electric Biltong Slicer

Our Product was developed by the Claasens family. Late Mr Willem Claasens (snr) a farmer and entrepreneur from Clocolan district South Africa, patented the spiral blade and commercialized the first rotating hand and electric biltong slicers.

Willem & Engela Claasens (Inventor)

In the years to follow Mr Claasens' sons participated in developing and manufacturing CLAASENS products. They grew up on the farm and excelled in various technical fields. The daughters are recognized for their interest and support they gave to their father and the business.

Second (2nd) Generation Siblings

Francois made a major contribution over the years. Several products have been developed such as sausage fillers, standard and adjustable biltong slicers, mincers and meat band saw. Many patterns and steel moulds for casting have seen the light of day. Today he is still involved in the business. His experience and technical skills as patternmaker are indispensable to the success of the foundry.

Roelf contributed to making steel dies and moulds and streamlined the machining process. His tool-and-die making skills set the standard for productivity and quality control measures. He has also developed several products such as the first generation meat band saw. The electric grater and alu-chunk slicer are currently still part of the product line. Jan and Jaap as fitter-and-turners, have made an impact over a long period of time through machining and general engagement with the manufacturing process. Products such as patty formers were added with success and are still manufactured today.

Regarding the third-generation family members, Stephan is presently involved in the business. As designer and technical draughtsman, he creatively conducts new product development from concept to launch. He is involved in the latest developed products such as the meat band saw, a range of meat mincers and a new series of sausage fillers as well as other food processing equipment still in process of designing.

Third (3rd) Generation Siblings

The current company, Claasens Designs CC, came into existence in June 2010 and manufacture and market the CLAASENS products. The need and contributing value of the products in the marketplace was the deciding factor to develop and grow the business. With minimal capital, and much perseverance, the company exists today as a recognized manufacturer of biltong slicers and meat processing equipment for small businesses and private use.

The leadership respect and honor the workforce for their loyalty, effort and disciplined labor to consistently realize products. Our production supervisor Piet Mosala works with the production workers and greatly contributes to our outstanding products.

Piet

The voice on our phone lines and the one that will assist you when you order any of our products is that of Gerda van Zyl. Our very capable sales & procurement lady standing at the ready to assist you with all your CLAASENS products needs. The other person you may encounter is Zelna Naude. As head of finance and administration she will professionally assist in these fields of business.

Gerda & Zelna

Willem is the second(2nd) generation still involved with the business. His engineering and MBA background contribute to product development and commercialization of the products. His knowledge and technical expertise helped to establish lean manufacturing processes, timely stock control and marketing of the products. He enjoys being involved with new product development. Willem currently manages the business with a focus on sustainability and business growth, particularly in challenging economic times.

Willem Claasens

Our Products:

The CLAASENS biltong slicer range is developed to include products that can slice variable thickness biltong slices (1mm to 9mm) and cut with ease through wet and dry biltong. Our biltong grater can process biltong into a fine dust or granule like texture (only dry) to be used in recipes or by elderly people.

Different types of slicers are available in hand or electric models. Cutting rates depend on whether you use hand- or electric biltong slicers models.

Biltong slicers such as the following are included:

Biltong Slicers

Alu-Wood Chunk Slicer

Alu Chunk Slicer

Hand Chunk Slicer

Electric Chunk Slicer

Hand Slicer

Hand Slicer Multi

Hand Slicer Pro

Electric Mini Slicer

Electric Slicer

Electric Grater

We also manufacture light industrial equipment for meat processing, such as the following:

Biltong shops, hunters and DIY meat enthusiasts can use these products to process carcasses of game, cattle, and sheep.

Meat Band Saw

Meat Mincers

Sausage Fillers

Patty Formers

Products to simplify food preparation in the kitchen or for campers are also part of the range of CLAASENS products. These include:

Butternut & Gem Squash Cutter

Jaffel Maker

Friendship Potjie

Vegetable Slicer

We shall continue to develop new essential products for food preparation and focus on aesthetics of the product and new technology developments in general. The products are manufactured from high quality materials such as cast aluminium, steel, stainless steel, and wood.

Value Proposition

The value we provide to customers is to ensure quality products for biltong and food processing through outstanding design, lean manufacturing, and customer service. Our products adhere to basic principals of performance, durability and safety.

The Way Forward

The Company is committed to new product development, involving innovation and NPD best practice principals. A positive entrepreneurial climate and management support help to develop, establish and maintain our products and the sustainability of the company.

We strive to understand and manage internal business factors and external economic factors that influence the company to maintain the success of the business.

We collaborate with customers to understand their need and provide the best possible solutions.

Copyright © 2025, Claasens Designs CC. Powered by DNA Super Systems and Shopify

Developed In-House by Jeandre Du Plessis - ( Systems Manager @ Claasens Designs CC )

Image Databases Used: Shutterstock, Png Tree